Brakeabsorber dynos works by braking the engine and measuring the force torque it takes to brake it over the RPM range. Water Brake Absorber 1893 produits disponibles 16.

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

Full-bridge strain-gauge load cell.

. Please slide to verify help help. Thus A area of cross section G G. Smooth Quiet Control With E-Stop Capability The Positorq Oil Shear Absorber brakes are a unique design for continuous tension control The unique Oil Shear Technology provides extremely smooth ultra quick response negligible wear with no adjustment required high energy Brake Engagement.

They also cost less than planetary-driven water brakes and allow far more design flexibility than hydraulic pumps. The first known toroid water brake was used to absorb 20000hp at 90 friggin rpm. As the turbine or propeller turns mechanical energy is transferred to the water due to turbulence and friction.

Water ft of packing ρG 62 Chapter 5 ABSORBER Design calculation of absorber We want to scrub Acetonitrile HCN and acrylonitrile in the absorption tower using water stream this is known as multi component absorption. For our absorber we will design for 42mm water in packing. Think about that for a second and let it sink in.

This type of absorber is widely used in dynamometer testing of various applications due to its relatively inexpensive and power-dense design. Their self-cooled rotors require no external water supply or resistor banks. It doesnt take very much water at all.

The paper investigates the effect of several design parameters of a dynamometer water absorber brake. Its fed by a 12 line and the output of the water brake just runs out of the brake onto the floor and goes into a drain. To complete the water dynamometer a control system.

For the dyno i will wire all the coils together. The existing system uses two individual absorbers. Sorry we have detected unusual traffic from your network.

YourDyno can acquire the data during a run and supports both manual and automatic brake control. Ideal for a wide range of markets water brake engine dynamometers churn water inside the housing and transfers energy by momentum exchange and water shear. There is a good paper titled Design development of Dynomometer water absorber by Karlis Banis.

Un design unique et une qualité durable ces produits valent vraiment votre argent. The resistance in each coil is 0945 ohms. It is a water brake.

Prêt à être expédié. The major advantage of water brake absorbers is that they offer a wide dynamic range meaning one dynamometer can test a wide range of engine speeds and engine torques the SF-902S dynamometer for example is rated for 15000 rpm and up to 1250 lbft of torque however it can also easily test small single cylinder engines that make less than 40 lbft. The shock caused by the acceleration of the water as it passes from pockets in the stator to the pockets.

Normally they are operated in 4 stages 2 coils either side for stage 1 4 coils either side for stage 2 so on. A hydraulic shock absorber water hammer arrestor may also be needed. In essence the fluid flow in the two designs are almost identical with the cupped design being more efficient.

Such applications include the bench testing of motorcycle automotive heavy equipment and even marine engines. Incorporated into a water brake engine dynamometer. The paper investigates the effect of several design parameters of a dynamometer water absorber brake.

This type of absorber is widely used in dynamometer testing of various applications due to its relatively inexpensive and power-dense design. A water brake is a type of fluid coupling used to absorb mechanical energy and usually consists of a turbine or propeller mounted in an enclosure filled with water. There are patents as far back as the early 1800s for this type of device the first one designed by William Froud to induce a load on a steam ship a big one too.

The more water flowing through the dyno the greater the braking force exerted on the device under test. Welcome to Buffalo Water. The Buffalo Water informational web site was created to help our customers learn more about one of our most important public assets clean and affordable water that meets or exceeds all water quality standards and to help guide you through the routine business transactions for your water account.

From phrases to jewels and even chains theres no limit to the 3D features youll be able to connect for your nails so get Resourceful and Permit loose. Toroidal-flow absorbers couple to engine either via the docking-stations telescoping driveshaft or the mobile-stands heat-treated 1-38x10-spline input shaft and your clutch disk or heavy-duty dampened drive plate. Early Superflows did have the open rotor design and are very capable of good results on small engines.

There are 8 coils either side of the stator 16 in total. Thus for 42mm of water m of packing height K 4 14 Fp 223 μ L viscosity of water at 45 0C 63 Cp G K4 v l - v 131 Fp μ L l 12 G 606 Kg m2sec. 3 to 30 Diameter Rotors for loads from under ¼ to over 3000 foot-pounds.

Semelle de freinage robuste pour camions chaussures avec pièces doublure collection 4709. Water brake absorber design If subtlety isnt your point Opt for one thing with a little bit more bling. A 10b g 2F by equation P in.

Andor hydraulic shock water hammer you must install protective plumbing devices. I believe how it works is the moving vanes inside the brake are close fitting to the stationary vanes and when water is introduced the fricition starts- more. The water customer must install a pressure regulating valve PRV and either a thermal expansion tank or a pressure relief valve to protect the internal plumbing system within their premises.

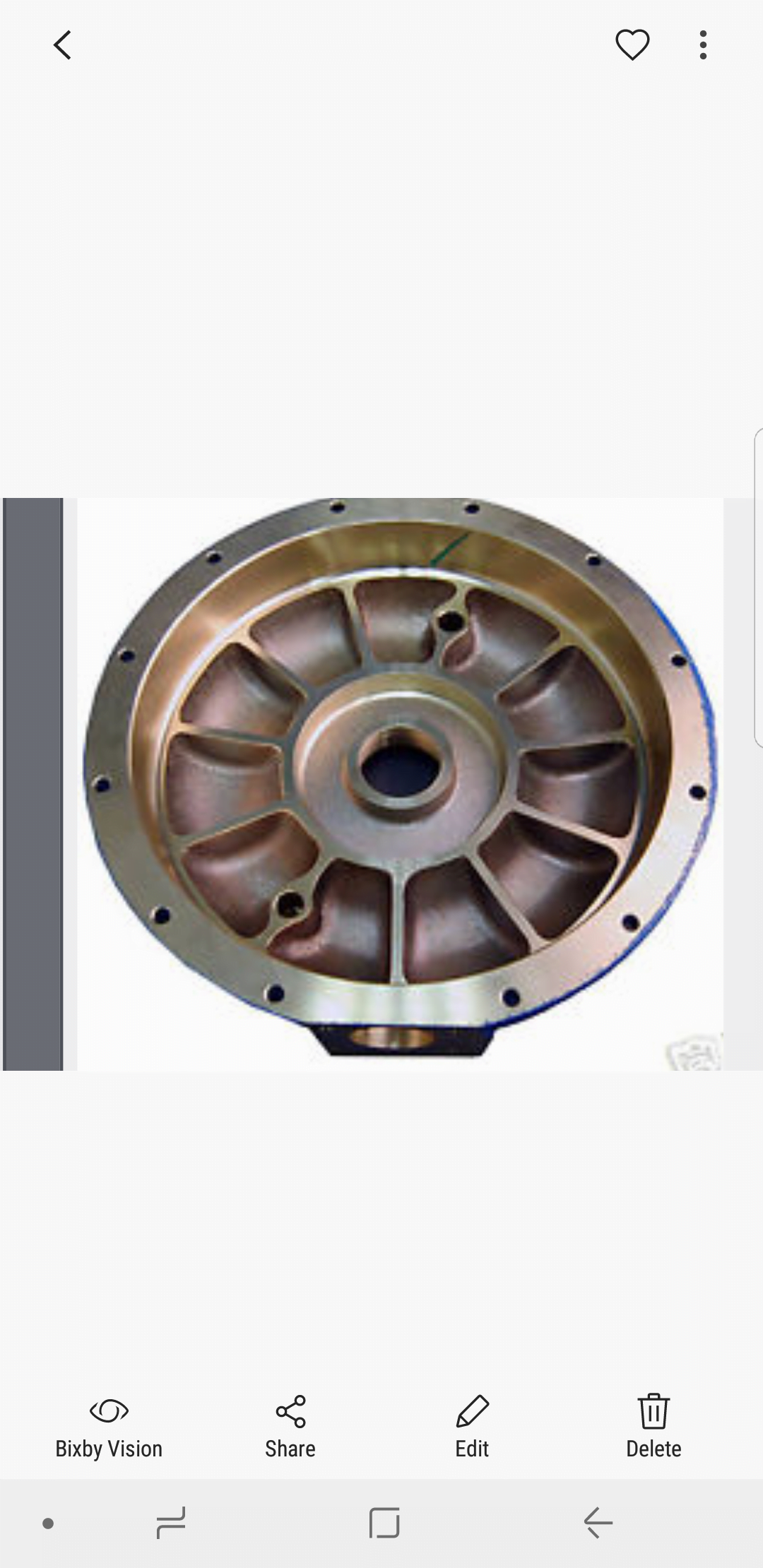

Higher capacities are available from tandem absorbers or via our overdrive. Water Brake Absorber Design. A single absorber unit is made of two stators on either side of a rotor as seen in Fig.

Each side of the stator is supplied one fluid inlet and outlet totaling four inlets and outlets for the system. Just leave the engine at wide open throttle and go through the RPM range by adjusting the braking force. Such applications include the bench testing of motorcycle automotive.

Pre-machined mounting plates fit popular GMFord bell-housing patterns may be custom drilled. Water Brake Dyno Advantages include.

Land Sea Absorbers Water Brake Water Brake Absorbers

Pdf Design Development Of Dynamometer Water Absorber Semantic Scholar

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

Pdf Design Development Of Dynamometer Water Absorber Semantic Scholar

Tech Talk Animation On How Water Brakes Work Youtube

Scratch Built Water Brake Questions Answers And Shared Experiences Yourdyno Com Forum

0 comments

Post a Comment